Learn about the different types of commercial metal fabrication used across various industries. Discover processes like welding, machining, forming, and cutting, which are essential for creating structural components, machinery parts, and industrial equipment.

Explore how fabrication techniques such as stamping, extrusion, and laser cutting are applied to meet the demands of construction, manufacturing, and engineering projects.

Understand which methods are best suited for specific applications and how commercial metal fabrication contributes to durable and efficient solutions.

The history of metal fabrication

Metal fabrication has been essential for human advancement for ages. Early humans first used basic metalworking techniques as far back as 5000 BC. They previously worked with easily accessible metals like copper and gold. The discovery of smelting brought forth the Bronze Age, around 3300 BC, enabling the creation of stronger tools and weapons.

The Iron Age, beginning around 1200 BC, revolutionised metalwork again. Iron and its alloys, especially steel, became essential for building sturdy structures and tools. With industrialisation in the 18th and 19th centuries, metal fabrication underwent significant advancements. Developments like the blast furnace and rolling mill allowed for mass production of metal parts.

Today, metal fabrication employs highly advanced machinery and techniques, influencing many industries. From automotive to aerospace, the evolution of metal fabrication continues to play a critical role in modern society. Learning the history offers insight into how technological progress shapes the future of fabrication.

What are the different types of commercial metal fabrication?

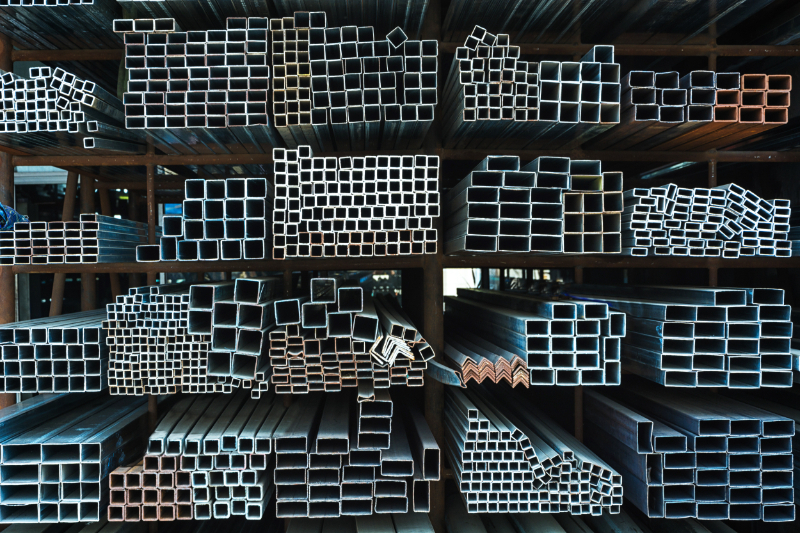

Commercial metal fabrication encompasses various techniques tailored to specific needs. Here are the four main types:

Structural Metal Fabrication: This type is commonly used in construction industries to create frameworks and structural components. It involves cutting, bending, and assembling metal sheets, bars, and beams to form buildings, bridges, and other large structures. High-strength materials, like steel, are often used due to their durability.

Commercial Metal Fabrication: This type involves creating metal parts and products used in consumer goods. Examples include appliances, furniture, and signage. This category uses metals like aluminium and steel to create smaller, precise components. It is done through techniques such as punching, cutting, and welding.

Industrial Metal Fabrication: Industrial applications require robust and resilient metal components. This fabrication type is used to create machinery, tools, and parts for industries like aerospace and automotive. The metal fabrication process here involves specialised techniques and high-strength materials. Doing this ensures the final products withstand intense operational demands.

Custom Metal Fabrication: This type of fabrication is tailored to meet specific client requirements, often involving unique designs. It can involve a variety of techniques including moulding, casting, and welding to create bespoke pieces. Custom metal fabrication is crucial for projects that need specialised parts not readily available through standard manufacturing.

Each type of metal fabrication serves a unique purpose across different industries, employing a range of techniques to meet varied requirements.

What Are Commonly Fabricated Metals and Their Properties?

Several metals are commonly used in metal fabrication, each with unique properties:

Steel is known for its high strength and durability, steel is one of the most commonly used metals in fabrication. It’s often used in construction, automotive, and industrial applications. Steel is malleable and can be formed into sheets, bars, and other shapes.

Aluminium is lightweight and resistant to corrosion. This factor makes it most suitable for aerospace and automotive parts. It's easy to work with, allowing it to be cut and moulded into various forms. Despite being lighter than steel, it offers decent strength.

Stainless Steel is not only strong but also resistant to corrosion and staining. It's often used in environments that need high hygiene standards, such as medical and food processing industries. Products made with stainless steel are more durable and have a longer lifespan.

Copper is an excellent conductor of electricity and is commonly used in electrical wiring and components. It also boasts good thermal conductivity, making it ideal for heat exchangers and plumbing systems.

These commonly fabricated metals each offer distinct advantages, making them suitable for various applications across multiple industries.

What does the metal fabrication process entail?

The metal fabrication process involves several steps, transforming raw materials into finished products:

Design: The first step involves creating a detailed design based on the project requirements. This can be done using computer-aided design (CAD) software. Accurate designs are crucial for ensuring that the final product meets specifications.

Cutting: Once the design is finalised, the raw materials, often in the form of sheets or bars, are cut into smaller pieces. Various cutting techniques like shearing, laser cutting, and punching are used to achieve precise shapes and sizes.

Forming: In this step, the metal pieces are bent, folded, or moulded into the desired shape. Techniques such as bending and rolling ensure the metal forms correctly for the next stages of the fabrication process.

Assembly: The formed pieces are then assembled. This often involves welding and other joining techniques to create the final product. The assembly must be precise to ensure the integrity and functionality of the metal product.

Finishing: Finally, the product undergoes finishing processes such as painting, coating, or polishing to enhance its appearance and protect it from corrosion.

Each step requires expertise and precision to ensure the quality of the final product.

How to choose a metal fabrication business for a commercial project

Selecting the right metal fabrication business for a commercial project involves several important considerations:

Look for businesses with a proven track record in the specific type of metal fabrication your project requires. Whether it’s structural, commercial, or industrial metal fabrication, their expertise should align with your needs.

The business should have the machinery, tools, and technology to handle the size and complexity of your project. Ensure they can work with the specific types of metal and fabrication processes required.

Quality control is crucial in metal fabrication. Ask about the quality assurance measures they have in place. High standards show the business will deliver reliable and durable products.

Review their portfolio or case studies of past projects. This will give you an idea of their experience and the quality of their work. Look for similar projects to yours, for example, if your factory needs new stairs or metal cabinetry, look for companies that have already provided these for commercial clients.

Good communication and customer service are essential. The business should be responsive to your queries and willing to provide regular updates during the fabrication process.

While cost is important, it should not be the only deciding factor. Ensure you’re getting good value for your investment by balancing cost with the quality and capabilities of the business.

By considering these factors, you can choose a metal fabrication business that will meet your project’s needs effectively. For expert metal fabrication services, consider contacting local specialists with good reviews and a strong portfolio of past work.

Representing your project's vision accurately, employing skilled professionals, and ensuring high-quality results are critical when selecting the right metal fabricators.

For further details about commercial metal fabrication services or to discuss your project, please contact local specialists in your area. Many will work with you closely to understand and provide your requirements.